Enhanced Oil Recovery (EOR) is like trying to squeeze the last drop of a condiment like ketchup, mustard or barbeque sauce out of a plastic bottle. Perhaps you’ve even resorted to taking the cap of the bottle off and using a knife to get the rest.

Similarly, oil companies aim to squeeze every possible drop out of an oil well with various Enhanced Oil Recovery methods to hopefully improve upon the average 35% recovery rate that traditional methods provide.

In some cases, choosing a suitable EOR method can go a long way toward obtaining twice as much from oil reservoirs, which can result in using the same well for many more years versus literally walking away from profit too soon in order to drill a new well somewhere else. Needless to say, the stakes associated with your selection are extraordinarily high.

- Engineered Salinity (ESal)

- Chemical Injection

- Microbial Recovery

- Gas Injection (use of CO2)

Let’s break down each of these quickly before we compare them.

Engineered Salinity (ESal) is a patented approach predicated on changing the salinity of injected water without adding any chemicals to the mix.

Chemical injection is an approach in which chemicals are pumped into a reservoir, changing the composition of oil or flow properties in an effort to make it easier to flow.

Microbial recovery involves introducing bacteria into the reservoir, changing the oil’s properties and creating agents that break down the oil’s surface tension. Hence, it flows more easily through rocks and into the wells.

Gas injection using elements such as CO2 will change the oil properties and add another drive within the reservoir to move more oil into production.

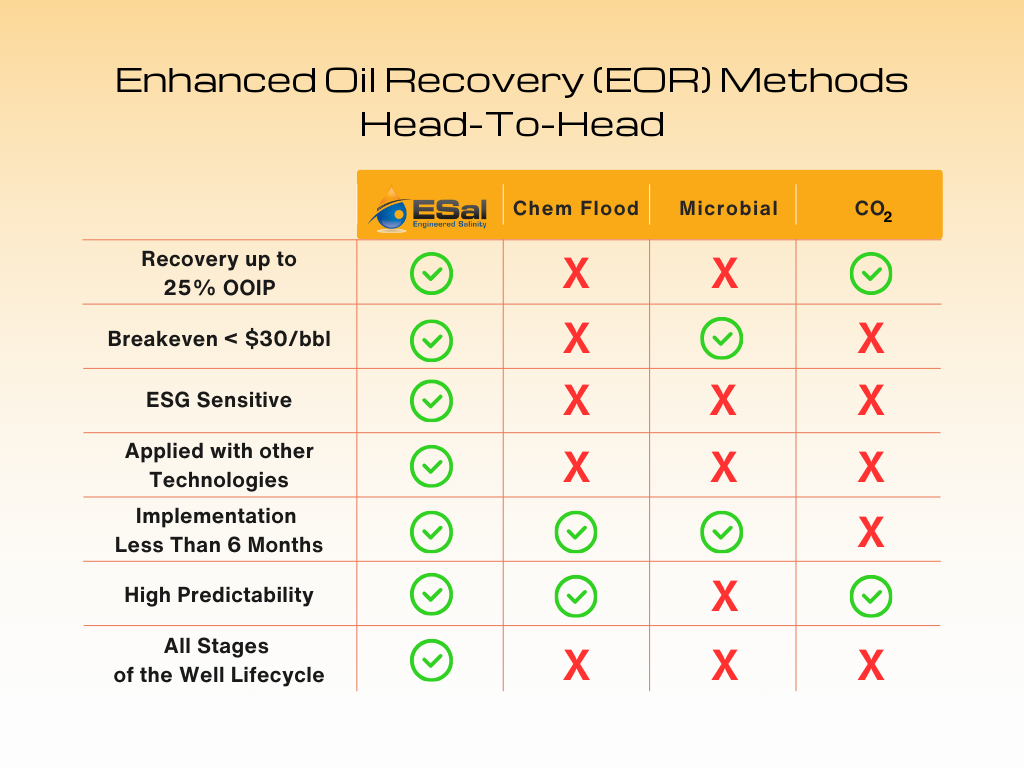

Now that we know the types of EOR methods, there’s only one thing left to discover: How they fare against each other in several key measurable areas, each of which has proven vitally important to engineers when considering EOR to supplement traditional drilling.

Recovery of up to 25% of Original Oil In Place (OOIP)

WINNERS: ESal, Gas Injection (CO2)

In numerous tests, ESal has consistently surpassed 15% of OOIP, meaning up to 50% in new oil production. Amazingly, no new investment is required to drill additional wells, build new pipelines or buy new equipment to reach that goal.

The effectiveness of gas injection can’t be overlooked for its ability to change a reservoir’s physical properties and increase oil flow. While expensive and, at times, logistically challenging, the upside of gas injection is that the recovery could be significant. Incidentally, there were only two areas measured in which CO2 injection excelled, the recovery rate in terms of OOIP being one of them.

OTHERS:

Microbial recovery and chemical injection may prove to be successful. Still, compared to ESal and gas injection methods, these bring more “ifs” involved in the way of expense, length of EOR processes and combination of elements, all of which have to align for them to achieve oil recovery at a high rate. It’s not impossible, but more questions are created to answer before you choose one of these techniques.

Breakeven < $30/bbl

WINNERS: ESal, Microbial Recovery

ESal is the unquestioned champion of costs per barrel compared to other EOR techniques, with costs as low as $1.62 per additional barrel. That’s simply an eye-popping cost per barrel, especially when you multiply that cost per all wells.

If we’re considering a runner-up to ESal, microbial recovery is likely to be more cost-effective when compared to chemical and gas injection methods. It’s not without costs of its own for producing bacteria, adding nutrients and the injection processes, but once those bacteria are identified, the costs tend to be lower than chemical and gas injection on an ongoing basis.

OTHERS:

Chemical injection costs can run high when the ongoing expense of obtaining specific chemicals is factored in. The same is true for the ongoing expenses of gas injection that call for continuous gas acquisition, injection facilities and high-cost infrastructure. Neither is likely to be as favorable on cost per barrel as ESal or microbial recovery.

ESG Sensitive

WINNER: ESal

At a time when the oil and gas industry is under growing scrutiny for its Environmental, Social and Governance (ESG) sensitivity, ESal’s solution for optimizing water salinity and changing the water chemistry is chemical-free, presenting a clear advantage in this category over other EOR methods.

Engineered Salinity’s patented approach calls for re-using large amounts of produced water in an existing well, meeting a high level of social and ethical responsibility that’s challenging for other EORs to speak to as strongly.

ESal’s technology can create more opportunity for recovery in an existing well rather than the standard practice of oil companies to continuously drill new ones – often leaving after only retrieving 35% of the oil within the reservoir at best.

Naturally, utilizing existing resources to the fullest is more favorable from an ESG standpoint. That said, ESal hasn’t forgotten about the profitable bottom line that oil companies are striving for, too. That’s why its team quickly points out that recovering so much more from an existing well and then frequently operating in that same well for many more years will bode well for profitability.

Great for the planet and great for revenue? Win-win in favor of Engineered Salinity.

OTHERS:

The chemical injection, microbial and gas injection methods have far more of an uphill climb to be considered ESG sensitive.

For example, as we view chemical flooding’s environmental impact, there are highly relevant questions to answer about the types of chemicals used and what the impact on ecosystems and water quality might be. Could injected chemicals lead to water contamination? If so, what risks are posed to a local ecosystem or community’s health and safety?

Gas injection can significantly influence environmental, social and governance impacts. Namely, compliance with emissions regulations and handling gases responsibly are essential here, which calls for a great deal of transparency throughout the process. The gas has to be transported to the field in pipelines and any produced gas has to be recycled. Call gas injection an EOR method that potentially requires higher maintenance to consistently showcase its ethical and social impact positively – more so than others on this particular point.

Microbial recovery, while not the absolute most ESG-sensitive method compared to ESal, is positioned to be seen as one of the more favorable EOR methods for environmental initiatives than chemical or gas injection. By relying on natural processes, microbial recovery can minimize ecological risks and leave a smaller footprint. Chemical usage during microbial recovery is minimal, which in turn enables it to adhere to safety standards more easily as well as responsible research and development practices.

Low CAPEX

WINNERS: ESal, Chemical Injection, Microbial Recovery

Keeping capital expenditures low for cost control is one thing, but extending the recovery timeline of an existing well simultaneously is another. This becomes crucial for an industry approaching a transition state as the oil and gas business could be on the brink of experiencing.

How can oil companies mitigate financial risk and maintain flexibility? In terms of CAPEX, we can take gas injection off the table from the start.

Engineered Salinity’s methodology calls for a minimal upfront cost, even as stages of required commitment progress. For example, the firm’s initial testing period on an existing well can be highly efficient, requiring little to no risk from an investment standpoint.

OTHERS:

Chemical injection and microbial recovery may also offer a lower CAPEX for oil and gas.

Microbial recovery doesn’t call for high upfront costs on technology and infrastructure because it employs natural microbial processes that aren’t as expensive to manage on an ongoing basis or to integrate with the existing oil infrastructure. Companies aren’t looking to introduce costly and new strains of microbes extensively, as any modifications are often minimal. That said, the degree of success of microbial recovery is often influenced by the conditions of a reservoir.

Similarly, the approach of chemical injection provides a higher degree of integration with existing oil fields, offering an adaptability that foregoes additional drilling (and cost with it). In addition, when a company is dealing with the challenge of high viscosity or low sweep efficiency, traditional waterflooding may not be the most efficient means to address the specific issue. Chemical injection offers a higher cost-effectiveness and efficiency for such unique conditions in the reservoir, especially in how its solutions cater to the particular characteristics of the reservoir. However, chemical injection is not very successful in reservoirs with higher salinity levels restricting its deployment.

Applied with Other Technologies

WINNER: ESal

Technologies for the oil and gas industries have often been centered on finding and producing new reservoirs, but it’s difficult to justify the growing expense of doing so as sustainable. Fortunately, technologies that improve existing reservoir wettability represent an exciting new frontier.

One EOR method clearly offers the best win-win of cost-efficiency and an ability to work in conjunction with other technologies: Engineered Salinity.

ESal’s methodology of altering the inorganic chemistry of injected water has consistently mobilized up to 15% of OOIP at a much lower cost than all other EOR methods. ESal’s approach can be used by itself or in conjunction with the other primary EOR technical methods of chemical injection, gas injection and microbial recovery.

ESal relies on computer modeling when fully deployed to understand how each reservoir’s salinity conditions may change. The resulting projections showing field results matching the lab within 1% accuracy can help the firm predict the well’s recovery rate and for how many additional years. No other EOR methods have close to as good an agreement between lab and field.

Implementation in Less Than 6 Months

WINNERS: ESal, Chemical Injection, Microbial Recovery

These three Enhanced Oil Recovery methods excel by emphasizing low disruption to the reservoir environment when introduced, whether changing water salinity, introducing chemicals or utilizing a microbial approach.

For example, in the case of ESal, an oil company can begin the relationship within two weeks with ESal’s use of a proprietary screening tool. Compare two weeks to the industry standard for screening one field: 4-6 years. If confirmation of a potential for wettability modification is made, the ESal methodology swiftly moves to laboratory testing (4 weeks), followed by full deployment in the field. Now that’s efficiency.

All three EOR methods offer less time spent upfront on pre-project assessment compared to gas injection, but they also are not subject to the various obstacles involved with gas injection (CO2). Gas injection can face a much higher level of regulatory scrutiny and far more potential modification of infrastructure via the planning, permitting and construction required for injection wells, pipelines and surface facilities. This makes gas injection impossible to implement within a six-month window.

High Predictability

WINNERS: ESal, Gas Injection (CO2)

The beauty of EOR applications is that they can be highly predictable based on the quality of data available and reservoir characteristics. That bears out in one out of four EOR methods receiving high marks for this category.

We can point to various factors that have influenced the predictability of EOR methods, whether it’s ESal’s altering water salinity, chemical flooding or gas injection that is used.

What begins with ESal’s proprietary screening tool – which is only the first step in measuring potential wettability modification – continues with ESal’s laboratory testing of oil and rock samples to define the precise amount of oil that can be recovered. If this weren’t enough, ESal further identifies opportunities for refinements during deployment. These process layers move from possible to probable to proven reserves forecasted within 1%-3% accuracy. As a result, oil companies learn the additional years of reservoir life, making long-term profitability much easier to project.

OTHERS:

There is also a certain predictability to chemical flooding and gas injection that microbial recovery does not offer. For example, let’s take chemical flooding. To obtain a concrete picture of how chemicals will interact with reservoir fluids and rock formations, the chemicals undergo extensive laboratory testing, providing a solid level of predictability of their field behavior. However, the laboratory projections of high recovery are usually scaled back in the field.

Gas injection is also based on well-defined scientific principles, laboratory research and field trials conducted over several years, enabling these studies to create a setting for accurate predictions to occur in the future. But in the end, gas injection relies on type curves, that is, historical recovery in similar reservoirs, to predict likely recoveries.

All Stages of the Well Lifecycle

WINNER: ESal

Measuring all EOR methods head-to-head throughout the well lifecycle gives us one of the most comprehensive views of which of the four primary methods outperforms the others after the exploration, drilling and primary production phases are complete. During the secondary and tertiary recovery stages, ESal’s technology profoundly influences sweeping efficiency, causing a change in wettability and improving oil displacement. However, the most exciting area for ESal’s methodology may occur in the later stages of the oilwell lifecycle, in which mature fields face abandonment. By altering the water salinity, ESal is restoring oil production to late-stage wells and giving several more years of recovery potential to fields once thought to have “tapped out.”

OTHERS:

Gas injection or chemical flooding may merit consideration among the EOR methods for optimizing production during waterflooding but require a deep understanding of the reservoir’s rock and fluid properties to determine if this is indeed the case.

OVERALL WINNER,

Enhanced Oil Recovery (EOR) Methods

Head-To-Head:

ESal (Engineered Salinity)

Only one Enhanced Oil Recovery (EOR) method, the Engineered Salinity method of altering water composition, met the criteria of eight broadly reaching categories, often appearing as the only suitable option among the methods.

For oil companies that look to enhance recovery of oil in place, maintain environmental sensitivity, implement a solution within six months, possess a high level of predictability and integrate with other technologies, ESal’s methodology stands to:

- Create greater profitability over time

- Minimize risk from the very beginning

- Forecast the lifespan and reserve capacity of a well within pinpoint accuracy

Other EOR methods are not without their strengths. Chemical injection offers fast implementation and high predictability. Microbial recovery provides an excellent price per barrel. Gas injection (CO2) can reach recovery levels up to 25% of OOIP.

Yet, ESal met or surpassed the criteria in every measurable success category, making it one of the most promising Enhanced Oil Recovery technologies for oil companies to watch.

So, to crown a champion for this segment of techniques, when you think of EOR, think of ESal.