Enhanced Oil Recovery (EOR)

A Smarter Approach For Production, Profit And The Planet

ESal

It's Not Radical Change.

It's Committing To Your Wells More.

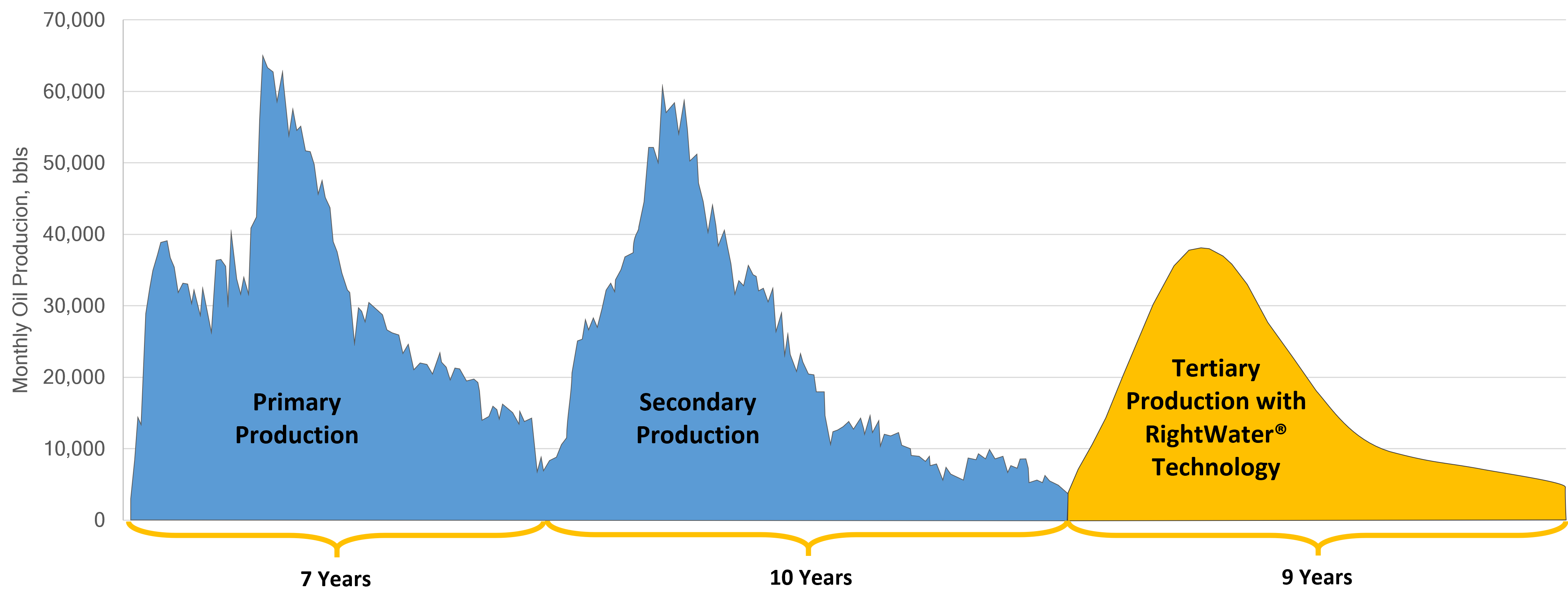

Let’s face it. We can’t continue to drill one new well after another, hoping to recover up to 30% of a well’s oil at a time. And let’s not talk about unconventional recovery rates. The days of living by that “boom or bust,” risky proposition are over. It’s not good business, it’s not good for the environment and it’s not an efficient way to get so much more out of what we have.

As the figures below show, spending more on E&P is not the way to go.

The solution we’ve developed at Engineered Salinity is designed to:

- Maximize oil recovery in existing wells WITHOUT CHEMICALS

- Create greater efficiencies without drilling new wells

- Produce higher quality oil more inexpensively

- Preserve capital

- Lessen the environmental impact of drilling

As a result, ESal is improving the stability of the industry from a production aspect as well as from a business aspect. One well at a time.

Instead of constantly drilling new wells and hoping for the best, the discoveries you’ll make will come from the fields you already have, using ESal’s technology to uncover more of those resources.

That’s the kind of approach with more business intelligence that yields greater consistency and keeps people in good jobs for a far more extended period.

How can we further enhance production in an old field?

Two words: Neutral Wettability.

The two figures below show the recovery dependency on wettability during waterflood. The plot shows both laboratory and field data for sandstone and carbonate rocks.

The figure on the left shows published data in which the best recovery occurs at neutral wettability. The normal condition in most oil fields (water-wet or oil-wet) restricts recovery to below 50%, which is why the global average recovery is 35%.

The figure on the right replaces the data with shaded regions and highlights ESal’s target, neutral wettability, where recovery is at its maximum.

Request a Screening

Why ESal?

Increased EUR, up to double digits, in your wells

Typically costs less than $4 per incremental barrel

No new equipment or change in normal operations

Increased production in as little as 6 months after deployment

Can be employed with chemical, thermal and CO₂ flooding to further improve results

Avoid or reduce freshwater usage and eliminate waste

Optimize wettability in your EOR Project with RightWater™

Frequently Asked Questions

There is much debate even today about the mechanisms, but the emerging consensus is changing salinity alters the wettability of the reservoir system to increase recovery (see our reference page for more information). At ESal our question is do we have enough practical understanding to make it work in the field. The answer is yes, we do. This knowledge is incorporated into our screening tool and our design process to provide you with the best chance of success. Our step-wise process of screening, lab testing, design and field deployment allows the client to de-risk the process saving time and money.

While there is limited field experience in this area, we know you can alter wettability in shale wells through our laboratory research and is currently being done with limited success with surfactants. In fact, many companies currently use surfactants in their fracking fluid which can be expensive ($250K/well). However, the basic conditions that allow us to alter wettability with salinity are present in shale. While it is early days, there is some published work that shows that wettability alteration by salinity modification works in shale (see our reference page for more information). Finally, the prospect of re-using produced water instead of disposing it is very attractive especially in basins where produced water volumes are high.

Traditionally, the answer is several years and millions of dollars of lab work and reservoir modeling. At ESal we have developed a screening tool to use your data on the rock, water and oil composition together with basic data on your field that gives you a numerical score within a few weeks (see our reference page for more information). This procedure provides a fast and reliable answer and identifies which factors are the most sensitive for your field. We can screen one or more fields quickly and provided you with the critical information at the speed of business.

Our screening tool and lab tests provide our clients with good estimates of potential benefits. Depending on the type of reservoir (shale, carbonate, clastic) and the stage of deployment the benefit will vary. However, in general both field and lab testing has shown the benefits are from 5-15% OOIP (original oil in place) in both carbonate and sandstone reservoirs and 2-5% in shale (see our reference page for more information). Avoiding expensive projects that provide little or no return is why you want ESal in your corner.